Finest Practices for Installing and Using a Cold Trap with Your Vacuum Pump

Guidelines that Should Be Considered When Installing and Using Cold Trap for Vacuum Pump

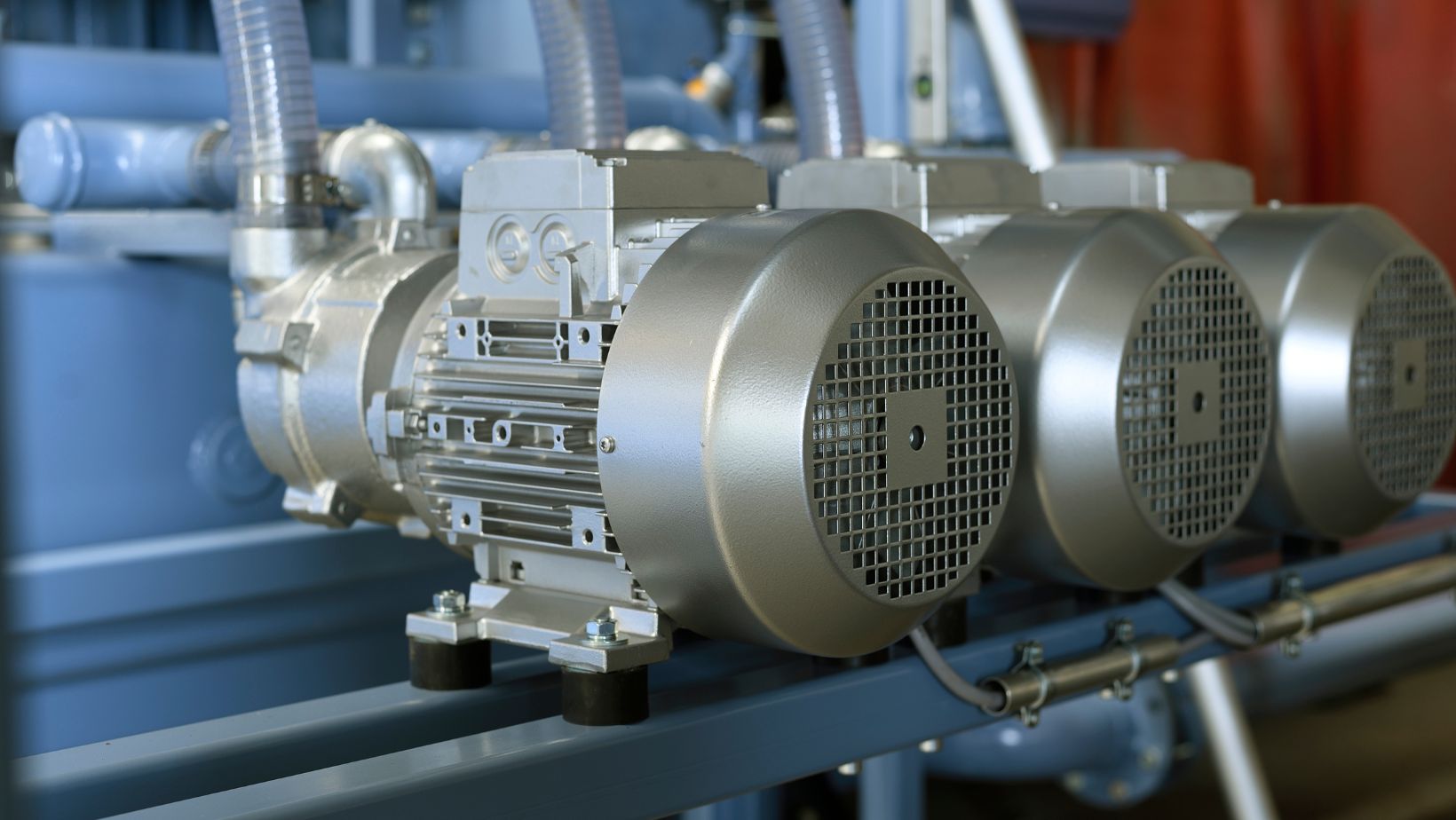

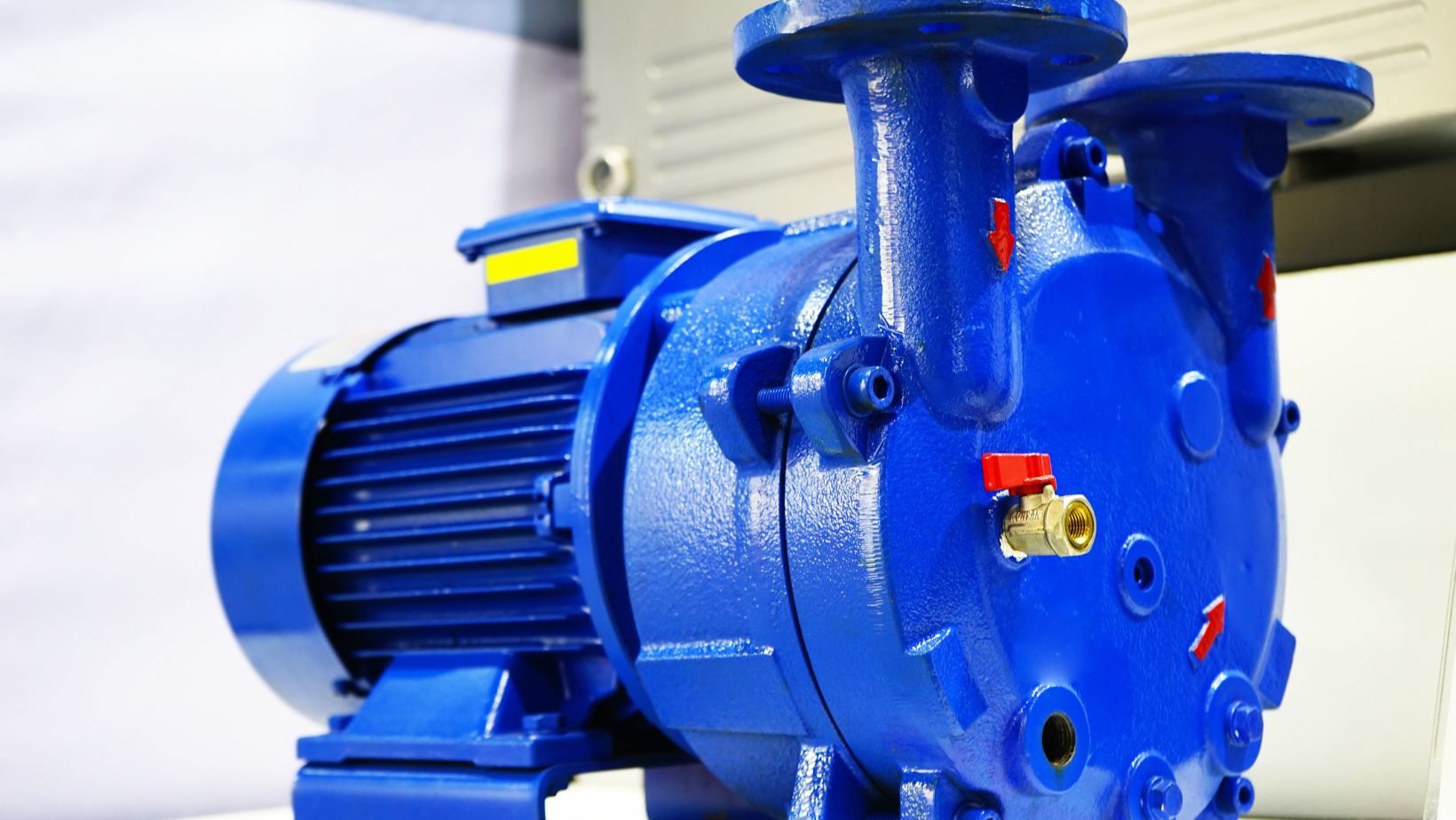

Vacuum pumps are used widely in many industries particularly where accurate distillation procedures are required such as in laboratories and factories. One of the most frequently combined elements of equipment with the vacuum pump in these environments is a cold trap. This article presents guidelines to help one utilize a cold trap with a vacuum pump, with more emphasis on distillation systems manufactures that supervise such systems’ installation.

Importance of Cold Traps in Vacuum Systems

Cold traps are always an important part of vacuum systems, especially if the purity and cleanliness of a working environment are critical parameters. These are equipment intended to reclaim liquid or solid solvents where they are vaporized before they can harm or deposit on the vacuum pump. For manufacturers of distillation systems, cold traps have proved essential in whatever design is used since they interfere with contamination, which may be detrimental to the quality of the end product. Cold traps also help to minimize the problem by condensing the vapors, which can otherwise cause mechanical breakdown or loss of efficiency in the functioning of vacuum pumps. Prevention of these vapors from reaching the pump not only preserves the mechanical aspect of the system but also assures the extremely high degree of purity required in processes that require very low levels of impurities, such as in the production of pharmaceuticals, whereby any impugned substance will lead to a batch failure. Also, cold traps can save a great deal of money by protecting vacuum pump investments from the destructive action of the uncondensed vapors, which lengthens the life of vacuum pumps and costly technologies.

Choose a Good Cold Trap

Selecting the most appropriate cold trap entails two key aspects, namely, the type of solvent, its properties, and the desired condensation temperatures. Manufacturers of distillation systems work with various solvents boiling at different temperatures and exhibiting rather diverse chemical properties of the substance; therefore, the cold trap must be fairly versatile and stable. In choosing the cold trap, factors such as the vapor load that is going to be experienced at the peak usage should be effectively considered so that the cold trap is able to handle the worst without fail.

Likewise, the choice of material for cold traps may be borosilicate glass or stainless steel since such materials are chemically inert and can withstand frequent application. Selection also requires the cold trap to have the right cooling means, either mechanical refrigeration or cryogenic liquids, in order to match the boiling points of the solvents being processed. This precise coordination also guarantees the fast reuse of solvents and conserves costs since it eliminates solvent loss, which, in turn, provides enhanced safety by pinching off all the fumes likely to pose a threat to workers.

Installation Consideration of Cold Traps

If cold traps are to be effective in vacuum systems, then the installation of these units should be properly carried out. Cold traps must always be located between the vacuum pump and the locality of evaporation to get optimal results when trapping vapors. It is placed right from the start to be the first barrier to the vapors that may harm the pump or deposit materials that are unwanted in the vacuum system. A key point to these is that the connection to each junction point in the system must be very high and leakproof in order to preserve the vacuum within the system and to ensure that no leaks compromise the efficiency of the system. Installation should also bear in mind that the operators should have easy access to the facility for maintenance, whereby one has to be able to easily remove and clean the trap when necessary. They also recommended that such traps should be positioned in ways that they can easily be checked and maintained so that in the process, there would be little or no interruption, with the maximum performance always being reached. It is also essential for users to adhere to the guidelines provided by the manufacturer, especially concerning installation angles and pipe diameter, among others, in order to have compatibility and efficiency throughout the vacuum system.

Practice

For the cold trap to be most effective, the conditions of operation must favor the condensation of gasses; such conditions include the flow rates and temperature of the system. Another important aspect requires constant temperature control and fine-tuning of the cooling procedure according to the volatility and amount of vapor distillation. The other thing to do is to control the flow rate of the vapors through the cold trap vacuum system to make sure that none of them is too much for the trap. Adherence to the best practices and manufacturers’ recommended practices involved when operating the system can mitigate problems such as back-streaming of vapors or counter-productive condensation formation. Periodic readjustment of these parameters serves to keep these components optimized between the provision of operational convenience and the priority of protection that must be sustained for the cold trap, as well as the vacuum pump that relies on it for sustained reliability and efficiency.

Maintenance and Troubleshooting

It is very important to always check the cold traps frequently because this will help to increase their service duration and, at the same time, increase their performance. This also entails occasional checks for abrasives or rust on the inner surface of the trap, cleaning the trap to eliminate the accumulation of materials that may block its drainage system, and changing other erode-able components such as seals and filters.

Failure to maintain the equipment leads to issues such as trapped air, which reduces the efficiency of the traps and, in turn, causes pressure in vacuum pumps that can harm the system. Troubleshooting also requires the knowledge of known signs, including ice build-up or vacuum loss, and making sure that they are not fixed for too long. A maintenance record can also be made, which will identify the periodic performance and the recurrent problems with the cold trap vacuum system for easier rectification. By maintaining the cold trap properly, along with solving the problem immediately if there is any, operators will be able to keep their cold traps performing their intended functions, thus offering security and effectiveness to the vacuum systems.

Following the outlined best practices in the integration and application of a cold trap in vacuum pumping within distillation systems , operators in the manufacturing industry will realize improved performance, safety, and effectiveness in the various operations. They help in maintaining the efficiency of cold traps and the vacuum pump so that in every distillation or vacuum turned process, the best results are obtained.